We revolutionize the world of education by combining augmented reality (AR) and virtual reality (VR) technologies to recreate real-life challenges through safe, effective, and unforgettable simulations. From fire extinguishing to emergency management, complex occupational safety training to skill-building programs, our solutions transform learning into an experience and training into a journey of discovery. By delivering the educational technologies of the future today, we are redefining the boundaries of learning.

Take your fire safety training to the next level with our Fire Extinguisher Simulation, powered by augmented reality (AR) technology. Designed to enhance safety and streamline the learning process, this application provides an immersive and interactive training experience.

Fire Extinguisher AR Simulation combines modern training methods with cutting-edge technology, making fire safety education more accessible and effective than ever. Whether you’re training your workforce or honing your own skills, this innovative tool is here to help.

Discover the future of fire safety training today!

Take your fire safety training to the next level with Fire XR! Developed with Extended Reality (XR) technology, this innovative simulation allows you to learn fire extinguishing techniques safely and effectively.

🔥 Realistic Simulation – Experience fire extinguisher use with XR technology, allowing you to practice proper techniques in a safe environment.

📍 Interactive Training Mode – Step-by-step guidance teaches the correct methods for handling different types of fires.

🛡️ Safe & Cost-Effective – Train efficiently without real fire risks or additional equipment costs.

🕶️ Full Compatibility with Oculus Quest 3 – Fire XR is designed exclusively for Meta Quest 3, delivering a highly immersive experience.

📊 Performance Tracking – Monitor user progress and success rates with detailed analytics to enhance learning and readiness.

Revolutionize fire safety training with Fire XR and be prepared for any emergency! 🔥🚒

Fire Extinguisher AR Simulation combines modern training methods with cutting-edge technology, making fire safety education more accessible and effective than ever. Whether you’re training your workforce or honing your own skills, this innovative tool is here to help.

Discover the future of fire safety training today!

Digital transformation in fire safety is accelerating. FireDOC AI is an advanced AI-driven inspection and reporting platform designed for firefighters and inspectors. The system analyzes fire risks in real time on-site and generates comprehensive reports, ensuring that safety standards are effectively implemented. This allows for a more informed approach to preventive measures before a fire and optimized response strategies during an incident. Additionally, the system continuously improves by learning from past inspection data.

🚒 Advanced Response Support: AI-based analysis evaluates fire risks on-site, determines hazard levels, and suggests optimal intervention strategies. Real-time data processing during fire incidents enables field personnel to make informed decisions. It also tracks fire dynamics live, helping identify the safest evacuation routes.

📋 Automated Inspection Processes: The system accelerates fire safety inspections by conducting regulatory-based deficiency analyses and automatically generating reports. Algorithms assess building structures and existing safety measures, identifying gaps or improperly implemented safety procedures. This enhances both periodic inspections and pre-emergency assessments.

⚡ Optimized Efficiency: Compared to traditional inspection and assessment processes, FireDOC AI delivers faster and highly accurate results, improving time management in field operations. AI support minimizes human error in manual inspections, enhancing overall safety. Moreover, findings are stored in a database, contributing to the development of long-term fire safety strategies.

📌 Regulatory Compliance and Risk Management: The system conducts fully compliant analyses in accordance with national and international fire safety regulations, identifying critical deficiencies and providing improvement recommendations. It continuously updates itself based on new regulations, ensuring that users always operate under the latest safety standards. Additionally, advanced risk modeling techniques predict fire probability and highlight high-risk areas in advance.

📊 Data-Driven Decision Making: FireDOC AI leverages big data analytics to assess past fire incidents, site conditions, and existing safety measures. Based on this analysis, high-risk areas can be identified, allowing firefighting teams to develop more effective strategies. Furthermore, the system is continuously updated through machine learning algorithms, leading to increasingly accurate predictions.

FireDOC AI is one of the most reliable technological solutions for professionals in the fire safety industry, minimizing risks and optimizing inspection processes. By providing comprehensive analyses, it enables firefighters and inspectors not only to assess current risks but also to anticipate future fire scenarios and implement proactive measures. Discover FireDOC AI to achieve the highest level of fire safety.

Discover the future of fire safety training today!

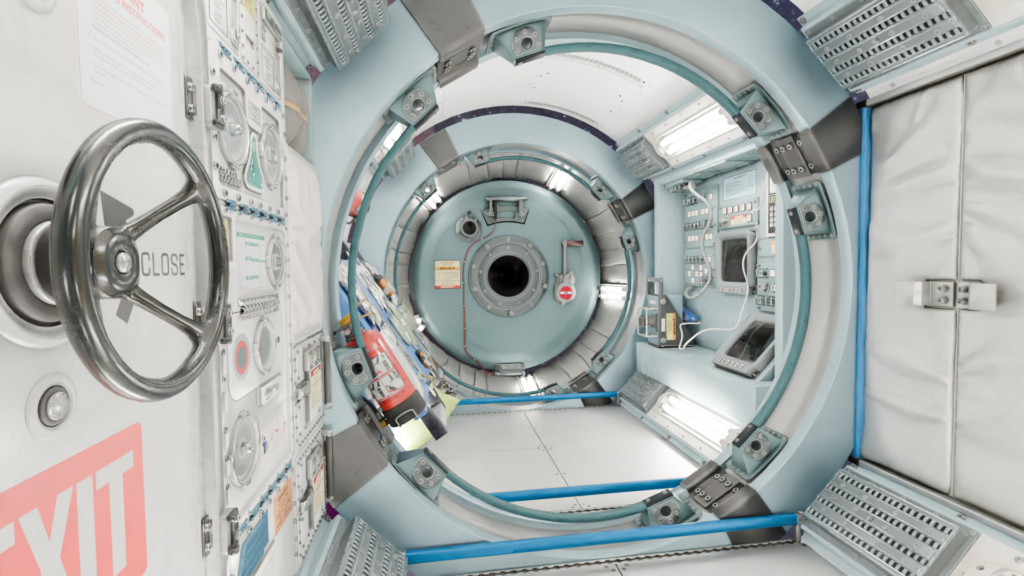

The M-STEM project is an advanced educational initiative supported by the European Union, designed to provide students with interdisciplinary scientific experiences through virtual reality (VR). This innovative VR application allows students to reinforce their theoretical knowledge through immersive and interactive experimental processes, contributing to a deep understanding of scientific methodology.

Biology Laboratory: Offers VR-based experiments in microbial ecology, genetic engineering, and cellular biology.

Chemistry Laboratory: Focuses on thermodynamics, analytical chemistry, and organic synthesis, providing an interactive environment to understand the dynamics of chemical reactions.

Physics Laboratory: Features virtual experiments on electromagnetic fields, quantum mechanics, and classical mechanics to explore advanced physics principles in a simulated setting.

Space Laboratory: Facilitates astrophysics simulations, space mechanics, and cosmology studies within a highly realistic virtual space.

Space Station: Provides students with immersive VR simulations of microgravity environments and experiences in space habitation and astronaut training.

M-STEM is a VR-powered platform that adopts innovative approaches in the natural sciences and aims to cultivate the next generation of scientists. The applications conducted in our virtual laboratories enhance students’ critical thinking and scientific analysis skills by offering hands-on, risk-free experimental experiences.

The development of optimal firefighting intervention techniques, systematic implementation of safety protocols, and the effective execution of crisis management processes make simulation-based training a crucial component. At XRealm, we have developed fire simulations supported by advanced interactive virtual reality (VR) and augmented reality (AR) technologies, allowing users to gain an experience as close to real-life scenarios as possible. With real-time scenarios and dynamic training modules, we enable fire response teams to enhance their strategic decision-making skills. Our simulations cater to a broad range of users, from firefighters to industrial safety experts, offering customized training content for all levels.

Ladder Rescue Simulation: The evacuation of individuals trapped in multi-story building fires is crucial for time management and operational efficiency. This simulation includes evacuation scenarios using hydraulic fire ladders that extend up to 32 meters and tilt up to 45 degrees. Users receive comprehensive training in firefighter rescue procedures by applying balance control, team coordination, and emergency intervention techniques in a realistic environment.

Electric Vehicle Fire and Accident Response Simulation: The thermal runaway risk and fire dynamics of electric vehicle batteries differ significantly from those of conventional vehicles. This simulation provides training on appropriate intervention methods for combustion and explosion risks at various battery charge levels. Additionally, critical variables such as isolation procedures, cooling techniques, and safe distance calculations are taught through hands-on experience.

Pump Simulation: Designed to ensure optimal pressure management in fire departments’ liquid supply systems, this training module covers the operational processes of three different fire pumps used by the Bursa Fire Department. Users learn to balance water flow rates, make proper pump connections, and effectively use chemical additives tailored to specific fire types.

Industrial Fire Response Simulation: Developed for large-scale industrial facilities, chemical plants, and oil refineries, this simulation covers different fire types and their corresponding suppression strategies. Users receive advanced training on gas fires, fires resulting from chemical reactions, and ignition processes of highly flammable materials, improving their emergency response capabilities.

Fire Extinguisher Usage Simulation: Aimed at enhancing fire safety awareness at both individual and corporate levels, this module demonstrates the functional differences between various types of fire extinguishers. Users experience which fire suppression agent is appropriate for different classes of fire, enabling them to act quickly and knowledgeably in emergencies.

At XRealm, we enhance fire safety training processes with modern technology, improving overall safety while optimizing costs. Our simulation-based training systems are designed based on academic research, providing participants with an interactive learning environment. Through realistic scenarios, we offer advanced competency-building solutions for fire safety experts, firefighters, and industrial operators.

Discover the future of fire safety training today!

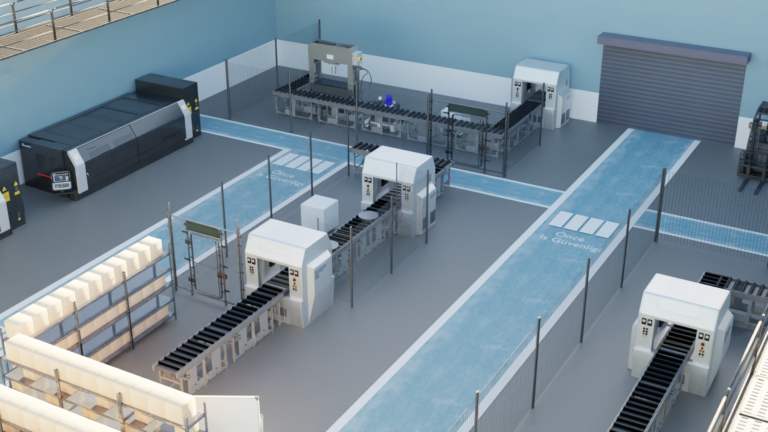

Developed to minimize scrap rates in manufacturing processes, optimize quality management, and enhance operational efficiency, VR Scrap Management Training provides employees with an interactive learning experience. By utilizing virtual reality technology, the training simulates the production environment, allowing employees to experience real-world scenarios and minimize errors.

This virtual reality-based application teaches employees how to accurately identify components that need to be scrapped, apply evaluation criteria in a practical manner, and effectively report the scrap management process. The training process enables participants to practice different scenarios in a virtual environment, reducing error rates in production processes. As a result, it contributes significantly to more effective production planning and improved quality control processes.

VR-based training allows employees to grasp information more quickly and ensures long-term retention compared to traditional training methods. The program is supported by step-by-step guidance, interactive assessment processes, and performance analysis features. Various scrap scenarios that employees may encounter accelerate adaptation processes, enabling them to make more informed decisions in real production environments.

Realistic VR Simulation: Users actively participate in the process by experiencing realistic scenarios in a virtual production environment. The virtual factory setting replicates real production lines, accelerating employee familiarization.

Interactive Learning Approach: Includes guidance and different scenarios to ensure proper classification of scrap parts. Provides real-time feedback to help employees correct mistakes.

Advanced Reporting Training: Teaches error-free data entry and analytical reporting processes. Employees can practice accurate reporting in a virtual setting to improve production line efficiency.

Minimizing Error Rates: Prevents incorrect classifications, reducing costs and production losses. The knowledge gained during training helps decrease errors in production processes, increasing efficiency. Performance Evaluation: Enables tracking and analyzing employees’ progress throughout the training. Personalized performance reports help identify educational deficiencies and develop improvement plans. Flexible Training Modules: The training content is designed to be adaptable to various industries’ production processes. Its applicability across different production lines allows for widespread use.

Leverage the advantages of VR technology to enhance industrial efficiency and strengthen quality processes.

Discover the future of fire safety training today!

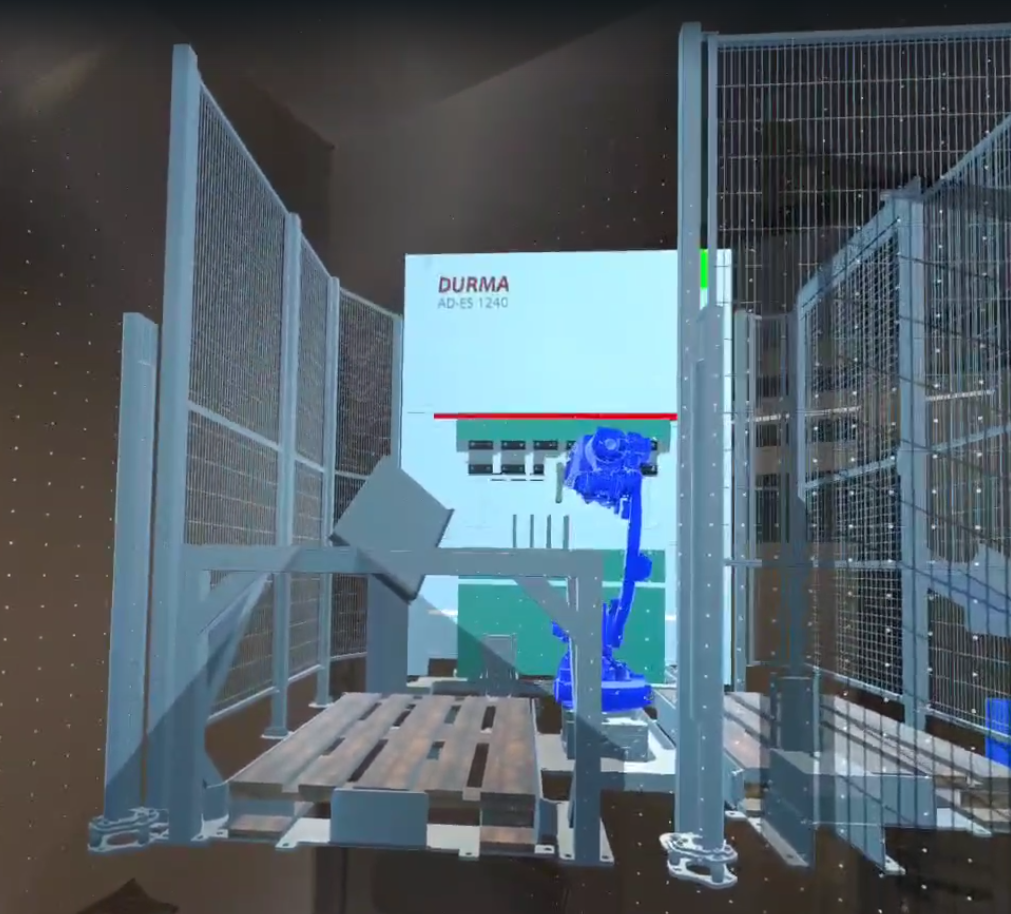

Our Extended Reality (XR) application is designed to analyze the working principles of industrial machinery in detail and depth. This system plays a crucial role not only for marketing professionals and trade show participants but also in research and development processes, supporting system engineering, performance optimization, and technical analysis workflows. With real-time interaction and advanced visualization techniques, it enables users to intuitively grasp complex mechanisms.

This platform provides a high-accuracy simulation environment for engineers and technical experts, facilitating the analysis of complex systems. The application allows for an in-depth examination of the operational dynamics of industrial machinery while also enabling the testing of various scenarios and the acceleration of optimization processes. XRealm XR serves as a powerful support tool for businesses to enhance production efficiency, minimize error rates, and improve operational decision-making mechanisms.

Engineering-Oriented 3D Modeling: All machine components are modeled with high precision and in accordance with detailed engineering principles, allowing for an in-depth examination of machine internal structures and interactions between components.

Dynamic Interaction and Scenario Simulations: Users can test different operational conditions and analyze how systems function under various circumstances. This feature helps engineers identify potential failures in advance and optimize preventive maintenance processes.

Physics-Based Simulation Integration: Dynamic simulations synchronized with real-world data provide detailed insights into machine component responses and operational dynamics. This enables the early assessment of critical factors such as material fatigue, wear, and mechanical stress.

Advanced User Interface and Data Visualization: Designed to facilitate in-depth analysis in R&D studies and technical presentations. The user-friendly interface allows engineers to easily analyze simulation results and gain technical insights through visualized data.

Modular and Scalable Structure: Equipped with customizable modules for various industries, the system offers a broad range of applications from manufacturing to automotive, from the energy sector to the defense industry. This makes it a flexible and adaptable solution for companies operating in different disciplines.

XRealm XR contributes to the evaluation of industrial machinery from an engineering and research perspective while providing a platform that accelerates decision-making processes and increases accuracy for technical teams. Positioned as an innovative analysis tool for system engineers, academics, and technical experts, this application enables a more systematic approach to technical processes, directly contributing to industrial development and innovation efforts.

XRealm – VR, AR, XR & AI Based Training And Education Simulations

© 2024 XRealm. Designed by XRealm Bilişim Teknolojileri Sanayi Ve Ticaret Limited Şirketi